| You are here: Technology - Precision Equipments |

|---|

Precision Equipments

All our main machining equipments ( Vertical Machining Center) are manufactured by Litz Hitech Corp and Top Well Machinary Co., Ltd. with following advantages,

|

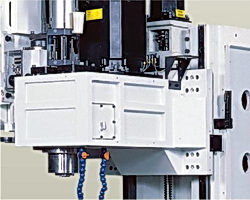

High Rigidity, High Accuracy construction design

- The enhanced ribs in major construction parts provide super rigidity for heavy duty cutting or high speed cutting. - The Y axis adopts 3 linear guide ways. It is free from load deformation. High speed feedrate and repeatibility accuracy are guaranteed. |

|

High Rigidity, High Speed tansmission system

- A central rod guides the counterweight. It ensures no vibration effect for Z axis high speed feedrate and cutting accuracy. - X/Y/Z axis adopts heavy duty linear way. It ensures the characteristics of high rigidity, low noise and low friction. High speed feedrate and contour cutting accuracy are achieved. |

|---|---|---|

|

|

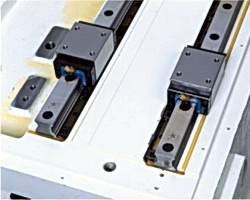

Optical Linear Encoder

All our vertical machining center equipped the high speed, absolute and incremental HEIDENHAIN optical linear encoder systems, to meet the diverse requirements of industrial machining.The optical linear encoders provide zero mechanical hysteresis and excellent metrology. The patented filtering optics could withstand a variety of contaminants such as dirt, dust and scratches ensuring CCEs' machines fitted with the linear encoders run reliably with almost no mechincal deviation.

|

|

|

|---|

Annual Calibration & Maintenance

All our vertical machining centers are scheduled annually for full scale calibration & maintenance by its original maker. This maintenance program ensures all our machines continue in the high accuracy & excellent condition.

| Advanced Annual Calibration & Maintenance Program | ||

|---|---|---|

|

Laser Inspection The full scale stroke is inspected and compensated by laser measurement instrument. The motion accuracy can be ensured. |

The IRD Dynamic Balancing The IRD dynamic balancing instrument calibrate the spindle displacement speed, and acceleration of the full speed range. |

Ball Bar Inspection The Reineshaw ball bar instrument calibrates the circulality and the geometrical accuracy to ensure the precise three dimensional motions. |

|

|

|

Production Equipments List

| Model/Maker | X/Y/Z Travel (mm) | Set | Facility |

|---|---|---|---|

| Vertical Machining Center MV-1400 / Litz Hitech Corp' | 1400 x 650 x 675 | 2 | Taiwan |

| Vertical Machining Center LV-1100 / Litz Hitech Crop' | 1100 x 520 x 550 | 6 | Taiwan |

| Vertical Machining Center TW1364 / Topwell Machining Co., Ltd. | 1300 x 640 x 610 | 10 | Taiwan |

| Vertical Machining Center TW2260-VTC / Topwell Machining Co., Ltd. | 2200 x 620 x 620 | 1 | Taiwan |

| Vertical center processing machine TW400HV / Topwell Machining Co., Ltd. | 450 x 450 x450 | 1 | Taiwan |

| Vertical center processing machine TW500HV / Topwell Machining Co., Ltd. | 650 x 600 x450 | 1 | Taiwan |

| Vertical Machining Center TW850 / Topwell Machining Co., Ltd. | 1000 x 650 x 600 | 8 | China |

| Vertical Machining Center TW1364 / Topwell Machining Co., Ltd. | 1300 x 640 x 610 | 4 | China |

| updating... | |||