| You are here: Technology - Engineering |

|---|

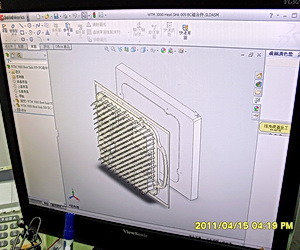

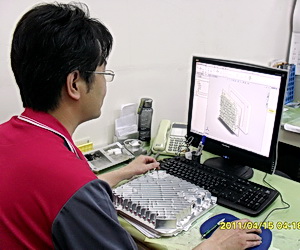

Drawing/File Accepted

In most cases, you may send your drawing/blueprints to us by PDF, DOC, or RTF format. However, if you need a comprehensive & quick feedback about your product design from our engineering perspective, you may add the following type of CAD files along with your inquiry.

CAD Files List

IGES - .IGS and .IGES STEP - .STP and .STEP Autodesk .DWG Autodesk .DXF Autodesk Inventor .IPT Autodesk Assemblies .IAM SolidWorks .SLDPRT SolidEdge .PAR .PSM Pro/Engineer Part .PRT Pro/Engineer Assemblies .ASM

Please ZIP all files before sending. |

|

|

|---|

Lead-time

In order to meet the upmost of customer's satisfaction, CCE's typical lead-time for every stage of manufacturing process is as the following,

|

|

|

|---|---|---|

| Quotation Lead-time: 3 working days | Sampling Lead-time: 7 working days | Production Lead-time: 2 ~ 4 weeks |

Batch Size Accepted

CCE is capable of accepting your order of batch size from 1 to 100,000pcs per batch.

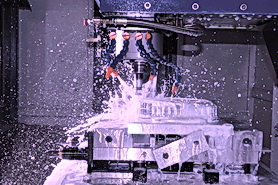

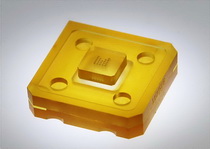

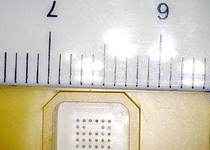

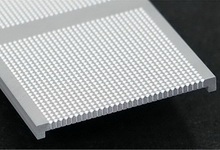

Micro Drilling

Small highly accurate holes are becoming a common requirement across a range of industries and applications. From hydraulic valves and spray nozzles to reflow PIN insertion jig, the ability to drill small, precise, repeatable holes is key to the integrity and functioning of a given product. Plus, many of the applications have volume requirements so drill time ultimately rivals cost and quality in terms of importance.

Enter CCE, with machines that spins micro-drills as small as 0.25mm with precision and repeatability in X,Y and Z. Our sheer speed combined with a micro-spray alcohol coolant system produces holes with smooth walls, well defined edges and virtually void of dross or recast.

- Smooth clean walls - Sharp well defined edges - High volume production - All in one micro-drilling. cutting, milling, and engraving |

|

|

|

|---|---|---|---|

|

|

|

|

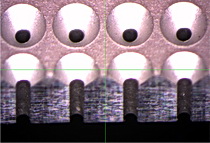

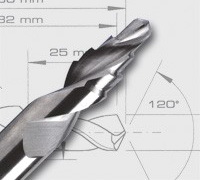

Special Tools

CCE has the dedicated tooling partner located next to our company who to desgin & supply the top-quality Solid Carbide tools. Well-knowing as a manufacturer of high precision CNC milling and engraving products, cutting technology has always been the driving force of our tool design research. CCE's superior technological tool design yields efficiency and quality in your CNC machined products. The Tool Specialists at CCE & our tooling partner are here to desgin & utilize the right machining tool for the needs of your machining application.

| CCE's Special Tools can solve many manufacturing demands such as chipped edges! We can custom manufacture carbide special tools per your product needs. Such like the custom ground tools for some instrument challenges, specialty drilling applications and mold making demands. The photo to the right is an illustration of a custom tool that can drill a through hole with additional counter-bores in one single plunge for cost-saving efficiency. |  |

|

|---|---|---|

|

||

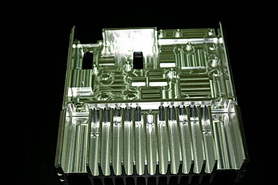

Cost Effective Solution

Are you looking for more information on who can make a more cost effective parts for your existing products? Look no further. CCE provides valuable insights into understanding, planning and executing a more cost effective solution to benefit the overall cost of your production.

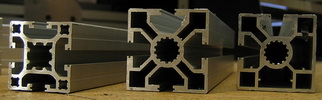

Our typical solution for cost effectiveness is based on the factor of your marketing & production plan. The possible solution can be the way to machine parts from the following methods,

| Block or sheet material |  |

|

|---|---|---|

| Blank of extrusion |  |

|

| Blank of die-casting |  |

|

| Forging blank |  |

|

Surface Treatments

Finishing is a process enhancing the properties of a metal to give it a decorative visual apperance and offer better protection against corrosion & scratch. Material like aluminium provides an ideal base for finishing.

For completing your machined products, CCE provides the following surface treatments of aluminium surface to fully meet your demand,

- Chemical passivation

- Anodizing

- Electroplating

- Electrodeposition

- Coating (or painting)

We also can offer the certs' of RoHS directives upon your request.